Protective Coatings Offer Lasting Superior Results for Car Wash Customers and Attractive Profits for Operators

Chipper New - Chemical Sales Manager

by Chipper New, Chemical Sales Manager, Howco Inc.

In the late 1970s, car manufacturers began adding a protective clear coat to vehicle exteriors, and this practice accelerated once lead-based paints were outlawed in 1978 and replaced with water-based acrylic enamel. Nearly every vehicle produced since the ‘80s has at least one layer of clear coat. This transparent paint preserves the integrity of the color paint layer and subsequently protects the primer coat from UV rays, oxidation, and damage from contaminants such as acid rain, tar, road salt, leaves, dirt, chemicals, and even bird droppings and pollen.

The clear coat is the vehicle’s first line of defense against these degenerative elements that might require extensive attention or repairs. High-gloss clear coats also provide vehicle paint with sustained luster. Hazy, dull finishes on vehicles often signal clear coat oxidation.

Protective coating technology has seen remarkable advancements over the past five decades. Three significant types of protectants developed over the years are carnauba wax, ceramic, and graphene coatings.

Carnauba wax is the oldest of the three varieties and provides a temporary layer of protection to the vehicle's paint, enhancing the shine and repelling water and contaminants. It offers a relatively straightforward application process but is less durable than its more advanced counterparts.

Ceramic coatings revolutionized the car care industry with their modern technology, increasing durability. These coatings are made of advanced polymers that create a molecular bond with the vehicle's surface, forming a protective layer with extended life.

The hardness of ceramic coatings surpasses traditional waxes and sealants, providing increased resistance to contaminants and exceptional water repellency.

Ceramic coatings applied to vehicles during the car wash process are like a clear coat “on steroids,” and the addition of graphene can take this to yet another level.

Graphene is one of the hottest current trends in the car wash industry, claiming a more protective, longer-lasting clear coat for customers, as well as a nice profit margin for operators.

Graphene is extracted from the mineral graphite, which is made up of pure carbon, one of the most important elements in nature and something we find in objects like pencil lead. Graphene stands out for being tough, yet flexible and lightweight, affording high resistance.

In the car wash industry, graphene is integrated into ceramic formulas to create a more durable layer of protection for vehicles, positioning its honeycomb structure as an ideal surface hardener and protectant.

The lifespan of clear coatings and protectants depends on several factors, including weather, where the car is parked, its exposure to various natural elements, and how often coatings are applied.

Protective coatings may be included in car wash package options or can be added a la carte. Low cost of application can allow for a healthy ROI.

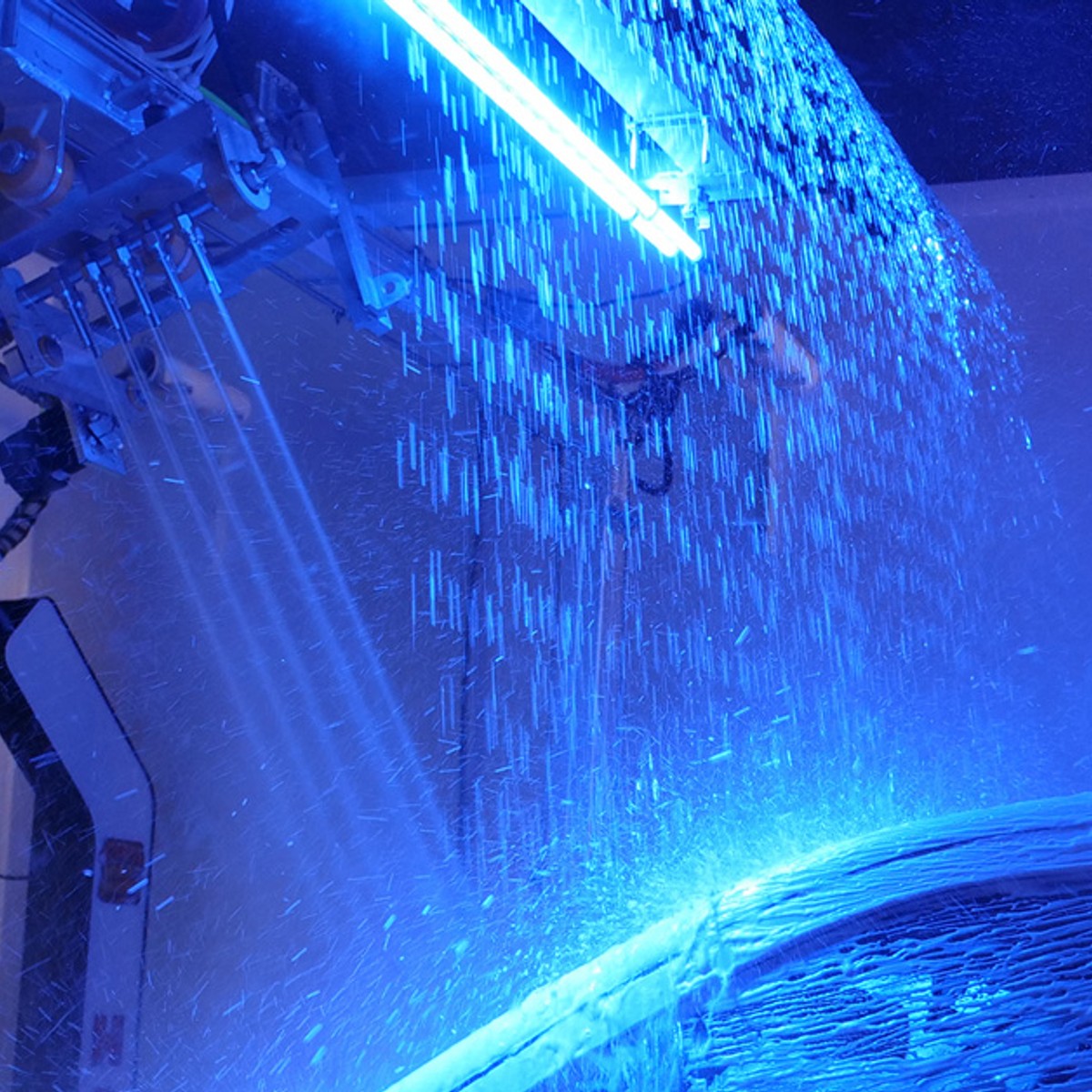

All automated car wash coatings are a finished product administered via applicators such as V-Jet Banana Foamers or K-Sticks. It’s the first product applied immediately following cleaning and before rinsing and drying.

For ceramic coatings, we highly recommend adding a new arch or applicator specifically designated for the product, which allows the wash to show customers the addition of the product to their vehicles. We’ve witnessed a return on this type of investment in as quickly as a month. ROI, of course, varies depending on the amount of product sold.

Any type of car wash, from self-service to full-service, can use these advanced protective coatings, and customers are requesting them more and more. Howco offers multiple protective barrier products that perform beautifully on vehicle surfaces. These super-concentrated protectant options are designed to shield all automotive exterior surfaces from the aforementioned damage culprits. Some protectants also assist with the vehicle drying process.

Please contact a Howco chemical representative to determine the best product fit and application for your wash operation. We will weigh durability and protection capabilities, as well as application and maintenance requirements; costs and long-term value considerations; and how these products can produce superior washes and attractive profits for you.

Related Resources

What are you waiting for?

Take the first step toward your business goals and reach out today. Our team is ready to get started when you are.