Optimize Winter Chemical Usage at the Car Wash to Maximize the Season’s Opportunity

by Chipper New, Chemical Sales Manager / Howco Inc.

Old Man Winter rarely spares anyone its rigors, and car washes are no exception. Preparing your car wash, including chemical products and delivery, for the cold season should be a regular part of your preventive maintenance plan.

As winter approaches, it’s a great time to revisit your chemical dilution ratios and usage of each product, because chemical performance varies in different temperatures.

Depending on a wash’s geographic location, chemical product use during winter changes as soil loads change, with the cleaning process becoming different because there are no tree droppings or pollen.

Also, brine used by municipalities in some regions for melting snow and ice on roads can create a different cleaning challenge, compounded by the chemical makeup of the solution, which can vary by locality. A Howco chemical representative can help determine what brine solution is used in your area and the best product to deploy for optimal vehicle cleaning.

With these variables, a winter preparation and maintenance exercise can help operators keep their chemical costs in check by determining how much cleaning power per vehicle is needed for the season.

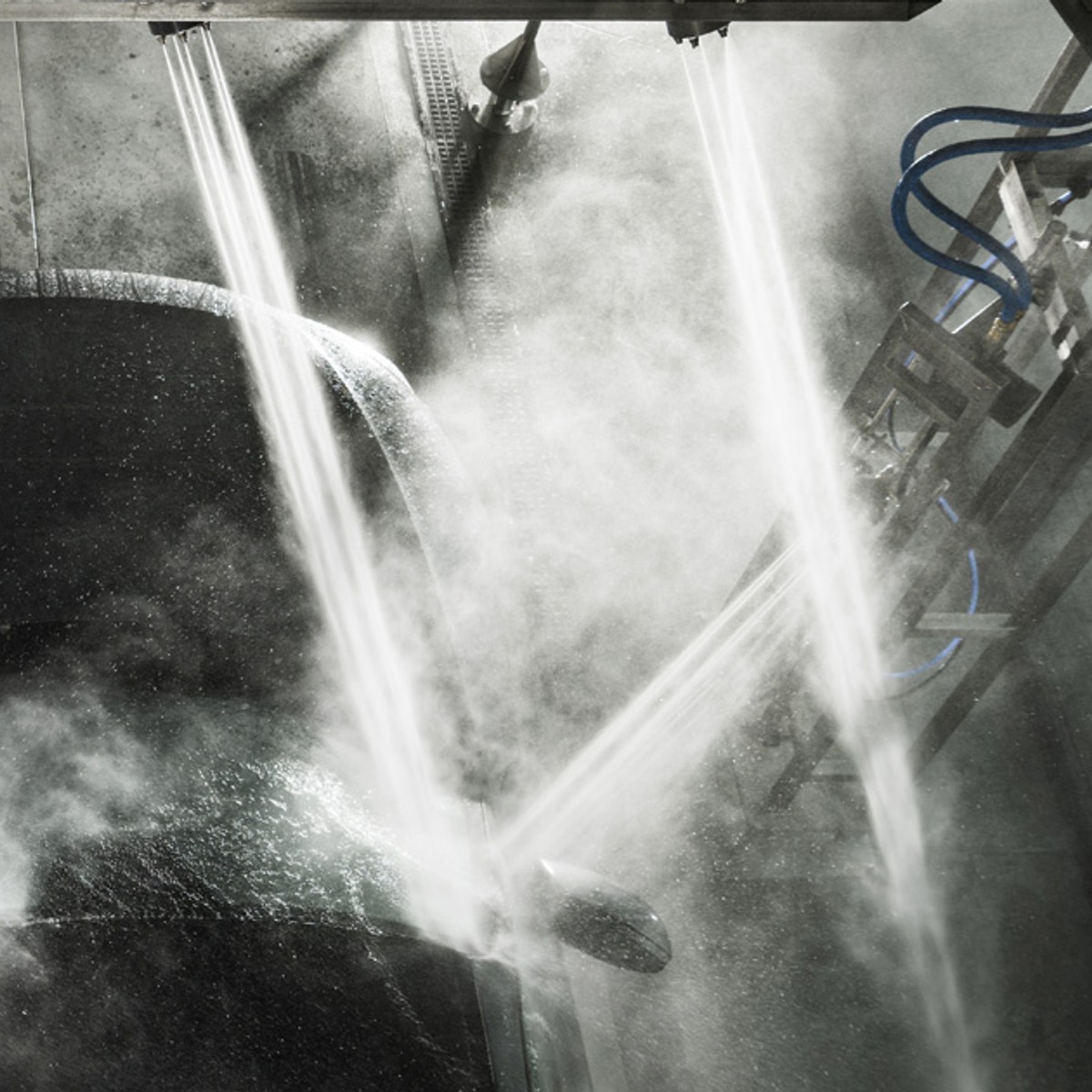

While you should be assessing all chemical applicators regularly, your winter preparation ritual is a particularly good time to check and clean the nozzles to address residue buildup and clogging and adjust their positioning and flow if needed.

During winter, it’s inadvisable to store chemical containers directly on concrete floors, as cold concrete can significantly affect and alter the chemical product therein. We suggest putting all chemical containers on wooden pallets, plywood, or even plastic grating (such as repurposed pit covers) to help insulate them from the low temperatures conducted by concrete. The TRUE-VUE 2 chemical management system also raises products off the floor.

Moreover, many chemical rooms are not temperature controlled, so it’s important to examine your storage area for any vents, door screens, gaps, or cracks where cold air could enter.

Inspect components such as air compressors and lines in which moisture can be affected by freezing temperatures, and check bay/tunnel heaters to ensure they are in good and safe working order.

It’s also prudent to forecast and plan for your busier winter months by reviewing car counts for the same period in previous years and ensuring you have enough product to cover your projections. You don’t want to find your wash short on product when business spikes.

In most markets, winter is the busiest car wash season, so seasonal preparation and preventive maintenance are paramount for maximizing the opportunity. Please contact Howco for more advice on optimizing your winter season.

Related Resources

What are you waiting for?

Take the first step toward your business goals and reach out today. Our team is ready to get started when you are.